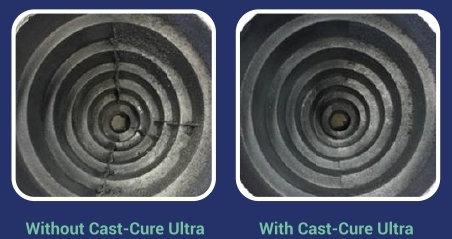

Sand Additive Cast-cure Ultra

Uniquely Invented Anti-veining Additive Cast-cure Ultra For No-bake, Cold- Box, Shell Molds/cores Applications In Grey & Ductile Iron Foundries.

Cast-Cure Ultra is invented by using scientific principles in our R&D centre to prevent thermal expansion defects. Cast-Cure Ultra is engineered sand additive made by inorganic minerals consistently more suitable than other foundry sand additives.

Cast-Cure Ultra is invented by using scientific principles in our R&D centre to prevent thermal expansion defects. Cast-Cure Ultra is engineered sand additive made by inorganic minerals consistently more suitable than other foundry sand additives.

.jpg)

Benefits of CAST-CURE ULTRA

- Eliminates veining, rat-tails, buckles

- Reducing casting defects & rejections

- Reduces machining and cleaning room costs

- Improves surface finish of castings

- Environmentally friendly solutions (no emissions)

Foundry Sand Additives Cast-Cure Ultra is a unique blend of high purity materials specifically designed to improve your casting process and efficiency. Foundries have noted that defect free castings and excellent surface finish results in a casting of higher value.

- Cast-Cure Ultra is compatible with all resin & binder systems.

- Cast-Cure Ultra do not contains any fine particles & volatiles.

- The flowability of sand remains consistent due to addition of Cast-Cure Ultra.

- Cast-Cure Ultra is in free flowing powder form and has unlimited self life.

Suggested Use

Cast-Cure Ultra is most commonly used 2-4% of foundry sand mixes. If sand mixes is 100 kg, mix 2- 4% Cast-Cure Ultra properly with sand, then add binders.

Turbochargers, Exhaust manifolds, Cylinder head, Engine block, Axle housings, Pumps, Water jacket , Ventilated brake disk , Oil gallery core, General housings, Railway castings, Hydraulic castings etc .

Application

- Grey & Ductile iron foundries in No-bake, Cold-box cores applications.

- Shell Mould Castings, Resin coated sand molds/cores applications.

Packing

Available in 25 Kg PP Bags with liner, Big Bags

With our company, you are guaranteed a consistent and high quality product through our constant drive for effective resource management of our raw materials & process controls ensuring long term availability of materials and future partnerships with our current and prospective clients.

Product GALLARY